Dramatic new products are core to the vibrant U.S. marketplace. Fashion, cosmetics, dining, groceries, consumer electronics, power tools, home decor, or disruptive new products—continuous roll-outs pique buyer interest and drive purchases. Reflecting evolving preferences and changing business needs of customers, all these segments drive innovation in another, all-encompassing arena as well: packaging design and manufacturing.

The U.S. corrugated packaging industry in particular is undergoing a significant transformation driven by changing market conditions. And this transformation is supported by a raft of developments in material science, recycling technologies, and sustainable design practices. In its quest for sustainability and circularity, the recycling industry has, perhaps surprisingly, become a focal point of change due to its dominant role as the container material for retail goods both in shipping and on store shelves.

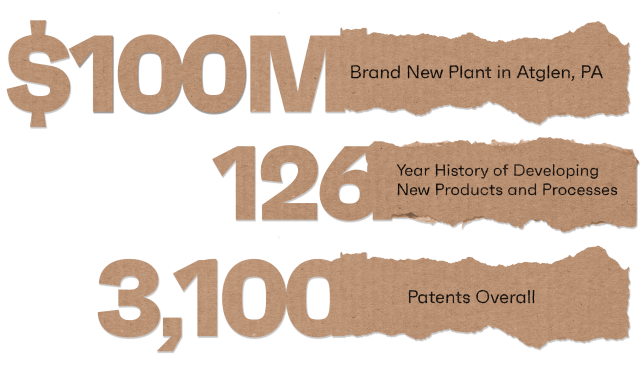

And maybe even more unexpectedly, one material is at the forefront of this revolution: humble corrugated cardboard packaging. A good example of the breadth of corrugated applications can be seen in the markets served by International Paper’s brand spanking new $100 million plant in Atglen, PA. It is producing corrugated packaging for clients across many segments: produce packing, processed food firms, beverage bottlers, shipping and distribution services, and e-commerce customers.

The responsiveness of the packaging industry to this continuous drive for change and improvement is nowhere more evident than in patents granted by the United States Patent and Trademark Office, where packaging designers and manufacturers, including International Paper, are prolific applicants. With a 126-year history of developing new products and processes, the world's largest fiber packaging manufacturer continues to innovate at a rapid pace, with nearly 3,100 patents overall.

Many International Paper patents protect innovative packaging designs and resulting functionality. International Paper’s patents also cover a spectrum of processes related to fiber-based packaging, including patents covering the chemistry and mechanical means of wood fiber conversion to corrugate linerboard, medium and boxboard; machining cardboard into blanks or boxes; even advanced technology for marking and tracking boxes. Increasingly, corrugated cardboard packaging is being designed to ensure recovery and recycling to create new products.

With a century-plus record of innovation, International Paper is a foundation for packaging advances among consumer products firms and even its competitors. Citations of International Paper’s patents as prior art can be found in the patents of companies like Westrock or Graphic Packaging, as well as global consumer brands, including Apple. Apple’s “Molded Fiber Packaging Inserts” patent cites not only International Paper patents, but those of other packaging companies.

Why would Apple get into the packaging arena? Its patent explains:

Packaging for consumer products protects products from damage and facilitates brand recognition. . . .effective packaging can be an important marketing tool used to attract customers. Packaging should hold and display a product in an aesthetically appealing way that catches a consumer's attention. Environmental considerations may play a role in designing packaging. For example, packaging may be designed to be environmentally friendly. Packaging made out of recyclable and/or biodegradable materials can reduce environmental impact. Maintaining desired aesthetics and function of packaging in view of such environmental considerations can be a challenge.

That triple challenge—combining aesthetics, functionality, and environmental sustainability—is the motivator in packaging development today, and International Paper’s patent development reflects this shift.

“Despite having eight corners, our boxes are circular by design because we create them with the end use in mind. In other words, our boxes are designed to be recovered, recycled and reused,” says Sophie Beckham vice president and chief sustainability officer at International Paper, where she works across the enterprise to advance sustainability strategy development and the company’s Vision 2030 goal implementation.

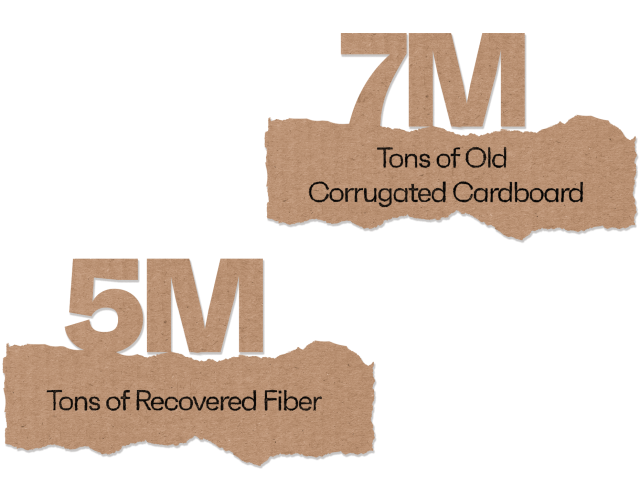

As customers now seek more sustainable packaging solutions, research and development at International Paper frequently focuses on recyclability and circularity in the fiber supply chain. With recycling facilities across North America, International Paper handles more than 7 million tons of Old Corrugated Containers (cardboard), linerboard, and mixed white paper that feed recycled fiber to its mills and those of third party partners, using more than 5 million tons of recovered fiber in its own mills—a truly circular packaging loop for its recycling services.

Research, and resulting patents, lead to a number of channels of development that improve recyclability of fiber packaging for International Paper’s own mills and the entire industry. Key among them are patented corrugated anti-wicking barrier coating formulations and ClimaShield® coatings that, unlike waxes and plastics, are able to be recycled alongside uncoated cardboard.

But there is much more than materials science involved. International Paper has developed carton designs that while strong and sturdy in use, readily break down for reuse or recycling.

International Paper works at every level of the circular economy to improve recovery and recycling of fiber; it is critical to its entire business. Producing about one of every three cardboard boxes used in the United States, a third of the fiber in those boxes is recycled content on average.

This makes International Paper one of the largest buyers of used cardboard globally. The company recovers, processes, buys or facilitates the sale of more than 7 million tons of fiber every year. That is 12 percent of the entire U.S. market for recycled cardboard. Since 2013, International Paper has increased its recovery rate of corrugated packaging by 93% and its overall recovery rate by 40%.

That recovery is good for communities nationwide as it reduces the volume of materials sent to landfill.

Customers of International Paper’s fully recyclable retail displays, ecommerce shipping solutions, and packages and containers—all designed for recyclability—can also contract for its recycling services. International Paper has a broad network of recycling facilities and an extensive reach through its National Accounts and Brokerage network of partners. International Paper, in conjunction with its partners, assures verifiable recovery in their customers’ supply chain.

Pushing the Limits on Cardboard Containers

Research and development projects may be initiated at multiple International Paper sites, including its Customer Commitment Centers in Memphis, Indianapolis and Aurora, IL, where some 250 structural designers, graphic artists and certified testing professionals collaborate on innovative packaging solutions for customers.

A small sampling of IP’s patents for corrugated containers, packaging and displays show the breadth of research conducted by International Paper. These patented processes and products are used by IP customers around the world to minimize waste packaging and facilitate recycling and circularity of the fiber.

A couple of recent examples of innovation are International Paper patents Leak proof container with adhesive attachment and Leak proof container with push lock body and rollover hinge, that allow corrugated boxes, including self-locking versions, to safely and effectively carry fresh meats.

Perhaps even more astounding are the large corrugated liquid bulk containers, such as International Paper’s SpaceKraft® bulk liquid containers made from corrugated paperboard. SpaceKraft containers have recyclability and circularity designed in, and may use International Paper’s proprietary coatings, which are compatible with paper mill pulping processes.

Reduce, Reuse, and Recycle

One avenue to sustainability is to reduce the amount of packaging, with eCommerce firms like Amazon favoring products that can ship in its own container. Known as SIOC (Ship in Own Container), this trend is driving brand owners to turn to International Paper’s dozens of patented SIOC designs, which are then tailored and customized for each application. Annually, International Paper’s customer commitment centers conduct nearly 400 SIOC projects working with more than 50 customers.

Another way to reduce packaging materials is to size packaging to the minimal dimensions required for shipping. Fanfold corrugated materials fill the bill to optimize packaging size on-the-fly in shipping centers, with machinery built by Packsize.

When making new boxes, International Paper only uses fiber from sustainability managed forests and recycled fiber, an environmentally sound practice. When possible, reuse of boxes can reduce the environmental burden of packaging even further. International Paper’s 2022 patent application for corrugated cardboard containers for repeated uses, along with a family of related patent applications, optimizes boxes both for rapid set-up and speedy breakdown. Another patent addresses a container design that is capable of being collapsed and re-erected: “While the described containers are effective to maintain their shape for protecting a product during use….It is difficult to collapse such containers following use so as to provide a flattened configuration for plural containers to be compactly stacked for storage and/or collection.”

Eliminating non-recyclability in packaging is also a key trend for packagers. In customer-facing eCommerce segments, unboxing a shipment to find goods encased in plastic foams and pillows can create a negative impact on brand perception. International Paper’s patent trail in recyclable shipping box cushions and fillers—from molded fiber product cases to corrugated wraps for breakable goods, demonstrates its focus on sustainable fiber-based inner packaging. It’s part of a paperization trend sweeping packagers and retailers trying to eliminate styrofoam and other plastics.

In the case of glass container goods, International Paper’s design experts say that with increased touches during order picking, outbound shipping, and last mile distribution to customers in the eCommerce supply chain, and “little to no consideration for box orientation, leaking and broken bottles are inevitable. Our solutions are designed to help you solve these problems.” Patents including one for “shipping insert and blank for forming same” and for “corrugated inserts for boxes containing wine or other breakable objects” cover International Paper’s work in this area.

What Lies Ahead

Work continues across the packaging industry on multiple fronts to expand the utility of corrugated and other recyclable fiber-based materials in packaging, including beverages. Beer brewer Carlsberg is developing a fiber-based bottle. Packaging innovator Ecologic already offers a hybrid fiber-based spray bottle that reduces plastic by 70 percent. Recyclability is designed into both offerings, and likewise for International Paper offerings such as an oven-ready corrugated baking tray. Similarly International Paper’s digital packaging printers, which allow no-waste printing of containers on-the-fly, use UV LED inks, meet OCC certification for recyclability and repulpability and meet the Greenguard Gold Standard (inks contain no hazardous volatile organic compounds). Specialized, recyclable inks printed on corrugated packaging are also the enabling technology for Ohmega, a customer engagement tool that verifies product registration and custom information for retail purchasers of goods.

Conclusion

In the packaging sector, patent developments by International Paper, brand owners, and a broad spectrum of stakeholders now incorporate recyclability not only for the sustainability benefits, but because the full cycle of packaging design, manufacturing, and recovery for circularity are a key part of the product marketing story. To win the hearts and minds of customers today, packagers and brand owners must make sure that their product, and the packaging surrounding it, has the full story—features, benefits, and sustainable, recyclable, packaging.

IP ClimaShield® Coatings and Patented ClimaGuard Medium—ClimaBin® Patent International Paper

International Paper ClimaGuard® medium technology, a non-wax solution to prevent moisture wicking and structural compromise, is applied to a range of corrugated packaging, from smaller containers and trays, to the large ClimaBin®, used to transport retail displays of bulky produce like watermelons. Developed in 2016, ClimaBin® had to be especially robust to cover low to high humidity environments that are common at produce packing facilities, which tend to be a combination of indoor and outdoor facilities. After packing is complete, the bins are transported to retailers, where the vibrant display stands out alongside other produce containers. International Paper has pioneered recyclable, water-resistant coatings like ClimaShield® and its patented ClimaGuard® medium. Based on innovative research and development, these coatings improve the recoverability and recyclability of corrugated boxes with an environmentally-friendly wax-alternative moisture barrier.

IP's Innovation Hubs

Packaging design is critical to the customer experience. International Paper employs a globally connected team of 250+ designers utilizing over 1.8 million designs to develop and deliver the best structures for your products' performance and marketability. At International Paper Customer Commitment Centers in Memphis and in Aurora, IL, the focus is on practical innovation, bringing new improvements to life. These can include reduced packaging cost through enhanced fiber utilization and package compression and by delivering the most effective specification and creative design for customer application. To consistently drive and deliver practical innovation, International Paper also offers developed a defined process called Customer Value Analysis or CVA. These audits or observations utilize a cross functional team of key IP stakeholders working collaboratively with our customers at their facilities.