In warehouses worldwide, the use of more radio-frequency ID tags, industrial robots/cobots and artificial intelligence (AI) continue to reshape the distribution inventory landscape. Such automation advancements can improve production levels by up to 20% in some e-commerce warehouse settings, according to logistics/supply-chain real estate investment firm Prologis.

In addition to technological developments, there is a more basic, cost-effective tactic that can pay steep dividends toward increasing operational productivity: conserving in-plant space. Optimized material handling and recycling management offer a triple-play of financial, operational and environmental benefits.

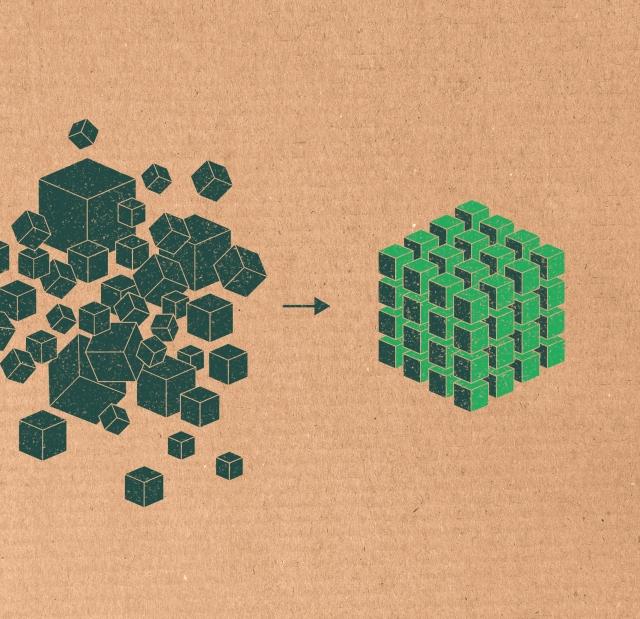

It’s no secret that bulky packaging devours valuable warehousing inches like Pac-Man feeding on arcade-game ghosts. In the recycling sphere, what’s old can be made new again but, if not compacted properly, post-use corrugated packaging (commonly called “cardboard,” see sidebar) takes up significant floor space. The accumulation of old corrugated containers (OCC, see box below) and mixed paper can occupy up to 15% of total building capacity, according to Canadian equipment supplier WarehouseWiz. This spatial problem is well documented by owners, COOs, CSOs, general managers, maintenance managers and recycling coordinators who operate warehouses, distribution centers, e-commerce fulfillment centers, commercial printing or packaging converting plants.

Conversely, square-footage conservation yields several financial incentives. OCC management is a necessary cost of doing business like any other. The flattening, compressing and baling of material promotes ease of handling as well as safer storage and delivery to paper production mills or processors, where it enters a pulper and can be transformed into different products, such as:

Recycled paperboard

The center fluting of corrugated boxes

Unbleached kraft paperboard

Compacted cardboard bales are easier to store/stack and secure, allowing for more safe and efficient use of space during transport. This can result in reduced transportation costs and a smaller carbon footprint for businesses. (Note: If poorly managed, can lead to

potential hazards for employees.)

The business case for space

Compacted material takes up a fraction of warehouse space, which means the size of storage and working areas can be increased. The use of balers and compactors reduces space needed for loose cardboard by up to 90%, per estimates from the Connecticut Department of Energy & Environmental Protection. Such improved efficiency has a positive impact on overall productivity, plus there are additional benefits, including a safer operation and decreased labor and other costs. Two other ways that dense makes sense, so to speak (and saves cents!):

- Compacting cardboard cuts operational costs by increasing floor space.

- When hauling to recycling facilities, bales are easier and more cost-efficient than loose material.

Over time, these savings can offset initial equipment investments. To achieve the most recycling return on investment (ROI), it is essential to assemble the right configuration of material-handling machinery based on specific facility needs. Through a free waste audit, International Paper (IP) works with customers to place the right equipment and maximize their floor space.

Optimized storage facilities allow for enhanced operations when fulfilling orders, picking and restocking, leading to faster delivery times and happier end customers. The financial bottom line: efficient recycling management practices can improve productivity and generate cost savings for businesses with warehouses, distribution centers and e-commerce fulfillment centers.

Paper and Corrugated Container Recycling Stats

- Paper is one of the most widely recycled materials in America, and paper recycling rates in the U.S. have consistently increased in recent decades.

- The paper industry recycles nearly 60% more paper today than it did in 1990, when the industry set its first recycling rate goal.

- According to the American Forest & Paper Association, the 2023 paper recycling rate was 65–69% and the 2023 cardboard recycling rate was 71–76%.

- 46 million tons of paper and corrugated packaging were recycled in the U.S. in 2023. That’s 126,000 tons per day.

- International Paper collects, sorts, and processes nearly 7 million tons of recovered paper annually.

Old Corrugated Containers: 3 Stats

- 34 million tons of OCC were generated in the U.S. alone in 2022, reports the American Forest & Paper Association.

- The recycling rate for OCC was 71-76% in 2023.

- The Fibre Box Association notes that “the average corrugated box is made with 52% recycled content. Fibre Box also states that “more than 50% of OCC recovered in 2019 was used to make new containerboard for more corrugated boxes,” and “an additional 10.4% was used to make boxboard (for primary packaging like cereal boxes).”

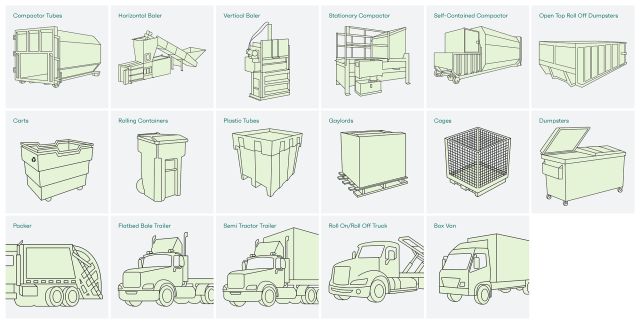

IP is dedicated to closed-loop recycling as part of the circular economy of renewable, fiber-based products. To promote sustainability and help customers meet their environmental, social and governance (ESG) goals, we offer equipment placements to help facilities contain loose and baled recycled materials, including:

- Horizontal and vertical balers

- Stationery and self-contained compactors

- Compactor tubes

- Gaylord container boxes, cages, carts

- Open-top drop boxes

- Locking roll carts

- Roll-on and roll-off trucks used for compactor tubes and drop boxes

International Paper’s recycling services are tailored to meet a facility’s specific needs. Efficiencies created by such installations can allow businesses to focus on their priorities.

We work with our customers to help them determine their optimal recycling program. We can conduct a workplace audit to review your current processes and equipment and work with you to determine your recycling equipment needs, sourcing and finance options.

The impact of a robust recycling program can be transformative to a business. As noted previously, the rewards of optimized material handling and recycling management extend beyond simply clearing valuable space. Reducing workplace clutter can provide financial, operational, safety and environmental benefits, increasing productivity and reducing downtime while also turning waste into a resource.

Please visit International Paper’s website to learn about our material handling and recycling solutions. If you already have a clear idea of your recycling needs, or are looking for a partner to help you determine the most effective and economical recycling plan, we can help.

Taking Inventory in 2025

Efficient recycling management practices are crucial to maximizing the productive use of space. In the United States, approximately 22,000 warehouses and distribution centers are in operation, handling the storage and movement of goods across the country. That number has risen by more than 50% over the past 16 years, according to WarehousingAndFulfillment.com and the U.S. Bureau of Labor Statistics. By some estimates, the average warehouse size is approaching 200,000 square feet - and growing. All these facilities collectively encompass some 15.5 billion square feet of space, translating to around 465 billion cubic feet (assuming an average ceiling height of 30 feet).

Such substantial growth reflects the evolving commerce and distribution industry, where the average cost of warehouse space now exceeds $8 per square foot, reports WarehouseWiz, and loose OCC and mixed paper occupy up to 15% of that space. Efficient recycling management, including compacting and baling, can substantially free up valuable storage real estate by as much as 90%, per some estimates (sources: Baling Wire Direct and Miller Recycling).

On a national scale, public data reveals that uncompacted OCC and paper would take up nearly 70 billion cubic feet in America—roughly the equivalent of 2.8 million garbage trucks each with a capacity of 25 cubic yards!

Board Definition(s)

Is there a difference between corrugate and cardboard? There are a number of different terms for very similar things that are used within the industry. These terms can be very confusing, so we’ve included a summary of short definitions to help you understand what the different terms mean.

Corrugated boxes are a combination of flat linerboard and a fluted medium, both made of durable kraft paper known as containerboard (see below). This combo makes corrugated boxes stronger and ideal for shipping.

Paperboard also is known as boxboard within the paper industry. Paperboard is thicker than regular paper but not as thick as cardboard. This material is used to package lighter items or to create more intricate unboxing experiences for items such as new mobile phones. The American Forest & Paper Association (AF&PA) cites other examples of common paperboard, including cereal boxes, medicine boxes, bakery boxes and tissue boxes.

Cardboard is called containerboard and corrugated within the paper industry, per the AF&PA. Cardboard is made of three layers of thick, heavier paper: The outside layers are flat and between them is a wavy, fluted medium. Cardboard is generally used to package heavier items; applications include shipping boxes, most take-out pizza boxes, point-of-purchase displays in stores and larger electronics such as televisions.

Additional resources for further information:

- U.S. Environmental Protection Agency (EPA) waste management guidelines →

- Warehouse Education and Research Council (WERC) best practices → (for purchase)

- Council of Supply Chain Management Professionals (CSCMP) resources → (membership organization)

- Material Handling Industry (MHI) reports and statistics → (downloadable)

- U.S. Green Building Council's LEED certification for warehouses →

- Earth911 – More Ideas, Less Waste → (website)